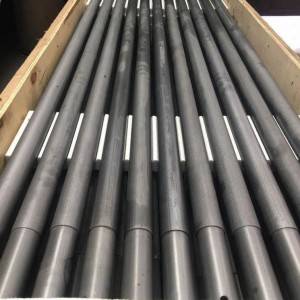

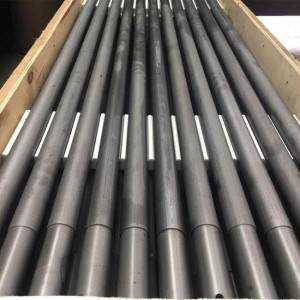

ʻO Roller

ʻIke kikoʻī:

Kuhi ʻia ka hopena Roller silikone CarbideHoʻohālikelike ʻia ʻo s me ka ikaika kūlou wela kiʻekiʻe-wela, ke kūpaʻa ʻana o oxygen, kūpaʻa ʻaihue nui, wāwahi manuahi ʻole i ka hoʻohana wā lōʻihi ma kahi mahana kiʻekiʻe, kūlou manuahi a me ka deformation

Noi:

Hiki ke hoʻopili ʻia i kahi kī ahi wela kiʻekiʻe o nā umu kaʻa wili no nā keramika o kēlā me kēia lā, porcelain hoʻomaʻemaʻe, kūkulu pākana, aniani a me nā mea magnet. ʻOi aku ka nui o ke ola ma mua o 10 mau manawa o nā wili keramika aluminika.

Nā Hōʻailona ʻenehana nui o nā huahana Silicon Carbide i hoʻopiʻi ʻia

|

'Ikamu |

ʻĀpana |

ʻIkepili |

|

Mahana hana |

℃ |

1380 |

|

Ka mānoanoa |

Bi / cm³ |

≥3.02 |

|

ʻO Porosity |

% |

< 0.1 |

|

<0.1 |

Piko kūlou |

250(20Mpa |

|

Piko kūlou |

℃) |

|

|

280 (1200 ℃) |

Elastic Modulus |

330(20Mpa |

|

Elastic Modulus |

ʻO Gpa |

|

|

300 (1200 ℃) |

Mahana Conductivity |

W / mk |

|

45 (1200 ℃) |

KMīkini hoʻonui hoʻonui wela-1× 10 |

-6 |

|

4.5 |

13 |

|

|

Mohs Paakiki |

Alkalinity a me Acidity |

Maikaʻi loaʻO ka ikaika kūlou o RBSiC (SiSiC) ʻO Roller

ʻo 250MP, ʻo 5 coefficient palekana he 5 mau manawa, a me ka lōʻihi o ka hiki ke lawe i 1 mika. Inā L ka lōʻihi o ka huahana, hiki ke helu ʻia ka hiki ke halihali ʻia me kēia ʻano:

ʻO ka ikaika kūlou o RBSiC (SiSiC) Puʻuwai Puʻupuʻu = ʻIlikai Waiwai 1 / L, Pūʻali Resultant o ka Uniform Distribution Force = ʻIlikai waiwai * 1 / L ʻO ka mahana adaptive o ka hiki ke hāpai ʻia ʻo 1380 ℃.

|

Papa Inoa nona iho |

Lōʻihi (m) |

Ana Paukū |

Hoʻoikaika nui ʻia (kg) |

||

|

L |

Hoʻohele like ʻia i ka hoʻouka ʻana (kg) |

D1 |

δ |

||

|

1 |

35 |

23 |

6 |

70 |

140 |

|

1 |

40 |

28 |

6 |

97 |

194 |

|

1 |

45 |

33 |

6 |

130 |

260 |

|

1 |

50 |

38 |

6 |

167 |

334 |

|

1 |

55 |

44 |

7 |

261 |

522 |

|

1 |

60 |

46 |

7 |

283 |

566 |

|

1 |

80 |

46 |

8 |

604 |

1208 |

D2

Hāʻawe: E like me nā koina

Ka manawa lawe: 1 * 20GP ipu lawe ma kahi o 10-20days

MOQ: 5 mau ʻāpana